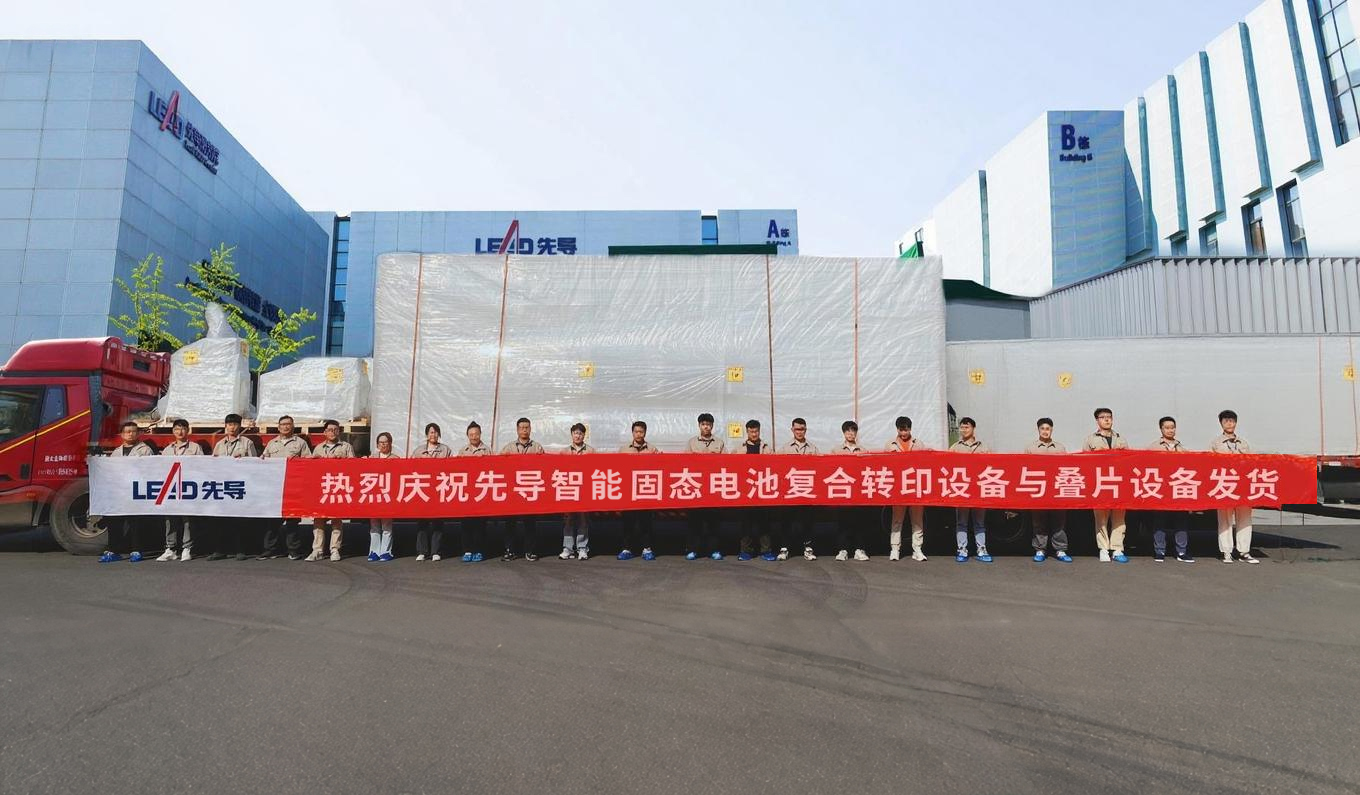

Lead Intelligent Equipment (hereafter referred to as LEAD) has recently completed the successful delivery of multiple sets of core solid-state battery manufacturing equipment—including composite transfer and high-speed stacking systems—to a leading global battery manufacturer. This milestone strengthens LEAD’s position as a global competitor in the solid-state battery sector and validates its capability to deliver integrated, full-line solutions beyond standalone machinery. The delivery also represents a significant step toward accelerating the industrialization of next-generation battery technologies in China.

Full-Process Technology Matrix

Building a Global Competitive Moat

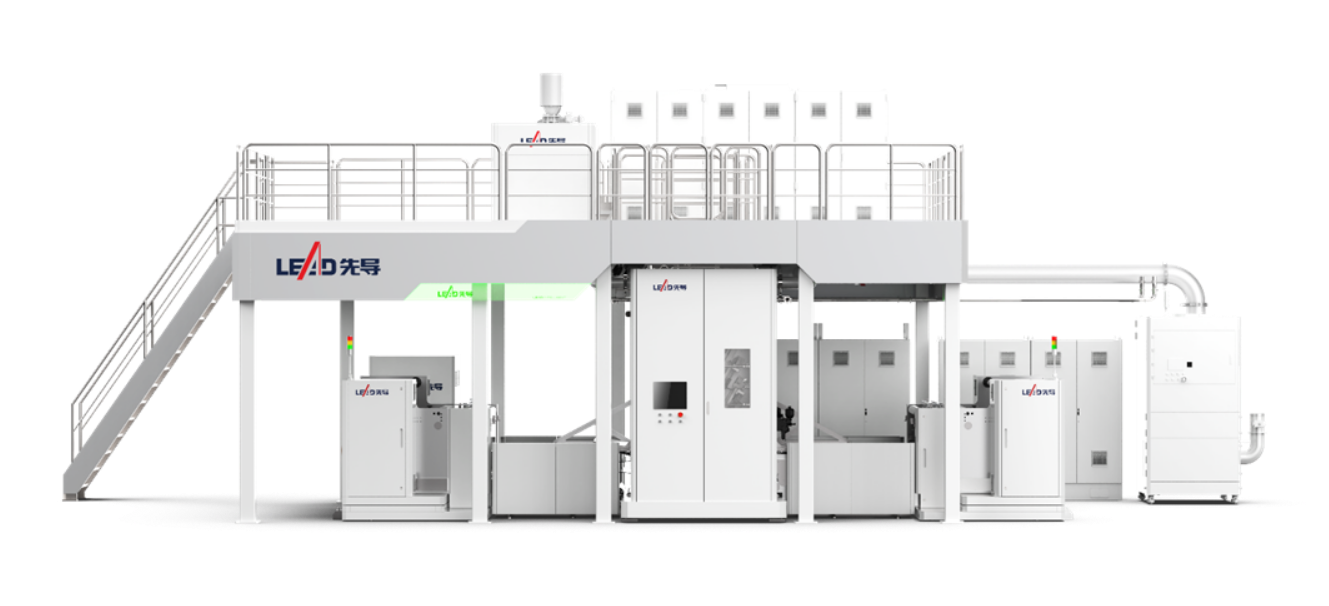

As one of the few equipment providers globally capable of full-line lithium battery system integration, Lead Intelligent Equipment (LEAD) has achieved comprehensive end-to-end process coverage for the mass production of solid-state batteries. Backed by 100% proprietary intellectual property, LEAD has developed a robust technology matrix spanning electrode preparation, solid electrolyte film fabrication and composite transfer, bare cell assembly, densification, and high-voltage formation.

Key highlights include:

- Dual-Mode Electrode Preparation and Coating Systems (Dry/Wet)

LEAD’s self-developed dry coating platform offers a wide process window and user-friendly operation, supporting film widths up to 1000 mm and thicknesses ranging from 40 to 300 μm. It achieves high-speed performance with coating speeds of up to 80 m/min for anodes and 60 m/min for cathodes.

On the wet side, the system features a specialized slurry formulation and precision coating structure, optimized for high-speed, wide-width solid-state electrode production. Both the dry and wet systems support multi-strip electrode sheet configurations, enabling high-throughput manufacturing.

- Next-Generation Electrolyte Film Processing

LEAD’s newly designed slurry processing system integrates dry powder mixing, kneading, and high-efficiency dispersion in a single platform—significantly increasing throughput while minimizing material degradation. A breakthrough in coating technology enables stable, high-precision mass production of solid electrolyte films with thicknesses ranging from 10 to 60 μm.

In addition, LEAD has developed a high-performance composite transfer system tailored for solid-state electrolytes. Supporting both continuous and intermittent operation at speeds up to 50 m/min, the system sets a new industry benchmark for scalable production.

- First-of-its-Kind Diaphragm-Free Stacking and Sealing Technology

Following the successful delivery of its first-generation solid-state stacker in 2024, LEAD has introduced a next-generation production model with significant performance enhancements. The upgraded system incorporates precision insulating frame fabrication, ultra-accurate sheet alignment, and high-precision dynamic pressing—dramatically improving stacking speed and alignment accuracy for diaphragm-free solid-state battery assembly.

- High-Pressure Densification System for Large-Capacity Cells

LEAD’s 600 MPa isostatic pressing system enables high-throughput operation at temperatures up to 150 °C by increasing the number of cells loaded per cycle. The system supports automatic loading/unloading and sealing bag handling.

Combined with an edge-insulating frame design, the process ensures cell integrity by reducing electrode displacement and preventing edge damage during densification.

Global Market Validation: Driving the Industrialization of Solid-State Technology

This latest delivery builds on LEAD’s earlier milestone—the successful deployment of the world’s first solid-state battery pilot line. Today, LEAD’s equipment is integrated into the supply chains of leading battery manufacturers across Japan, South Korea, Europe, and North America. The company has established deep partnerships with top industry players, delivering critical systems—including dry electrode lines, electrolyte film production lines, high-speed stackers, and isostatic press systems—to a diverse range of battery producers, automakers, and next-generation technology companies.

LEAD has received overwhelmingly positive market feedback, with its solutions earning repeat orders and broad industry recognition. At the 2025 Solid-State Battery Technology & Application Summit—hosted by Gaogong Industry Institute on June 10—LEAD was awarded the title of “Pioneer in Solid-State Industrialization Collaboration” in recognition of its full-line innovations in solid-state battery manufacturing equipment.

From localized process breakthroughs to system-level integration, LEAD continues to drive the industrialization of solid-state batteries through its dual innovation model of “equipment + process.” This latest delivery not only showcases LEAD’s technical leadership but also reflects China’s rising influence in supplying advanced manufacturing equipment for the global energy transition.

Looking ahead, LEAD is accelerating the development of its next-generation solid-state equipment platform. By delivering smarter, more efficient, and globally competitive manufacturing solutions, the company remains committed to advancing high-performance energy storage technologies worldwide.